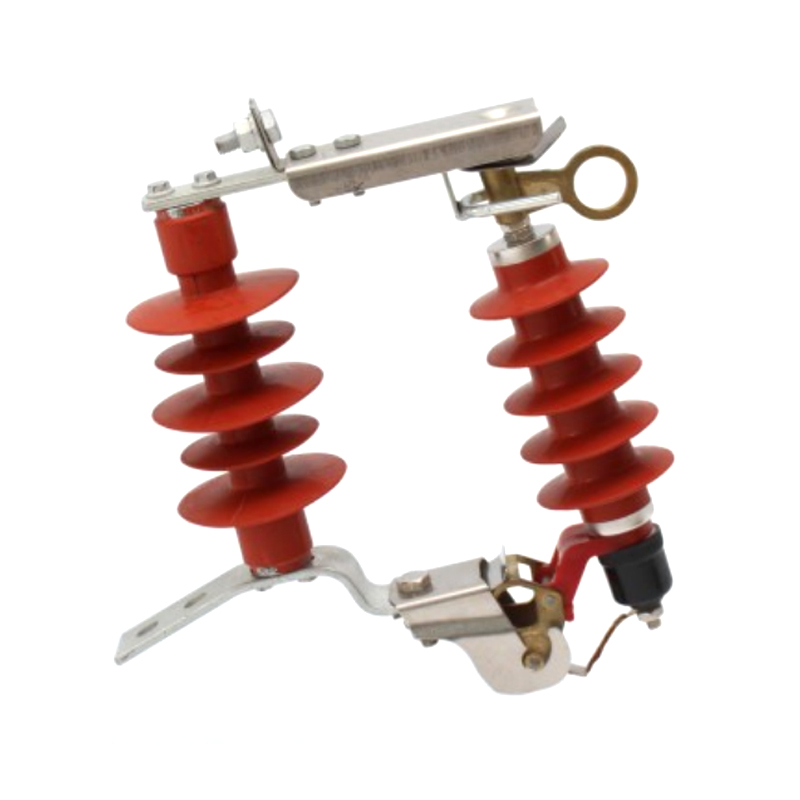

1. The arrester unit can be electrically loaded and unloaded at any time, making it ideal for locations where power outages

are not advisable.

2. Equipped with a disconnector, the arrester unit automatically flips down and deactivates in the event of a fault, ensuring

the line remains operational.

3. The unit's flipping down upon malfunction creates a conspicuous sign, facilitating timely detection and subsequent repair

or replacement.

4. The lightning arrester adopts a composite jacket, and the drop mechanism adopts a composite pillar, which has good

hydrophobicity and strong pollution resistance.

Fall Arrester

The HY5WS-17/50DL-TB drop-type lightning arrester is a modified distribution zinc oxide arrester cleverly integrated into thedrop-type structure of the fuse, allowing for easy inspection, maintenance, and replacement using an insulating switch rodwithout interrupting power supply,. This not only ensures the uninterrupted operation of the line but also significantly reducesthe workload and time required by maintenance crews. It is especially suitable for locations where power outages areundesirable, such as postal and telecommunications facilities, airports, stations, hospitals, and bustling commercial areas. Theperformance of this product is identical to that of a distribution arrester. The second-generation drop-type arrester features adisconnector. in the event of an arrester malfunction, the disconnector is activated by the power frequency short-circuitcurrent, causing the disconnector's ground terminal to automatically disconnect, This allows the arrester components to fipdown and deactivate, preventing further accidents and facilitating timely maintenance and replacement by maintenancepersonnel. The flipping mechanism is akin to that of a fuse causing the fuse tube to flip due to the melting of the fuse wire.Our company utilizes the world's most advanced RW12 drop mechanism,characterized by reliable contact,flexible switchingand advanced components including non-rusting steel covers with composite pillars. lt offers anti-pollution capabilities, rapidresponse, a wide current range, and can withstand specified current surges and operational loads, The product performancemeets the national standard GB11032-2000 (egv!EC60099-4:1991) Metal-oxide Surge Arresters without Gaps for A.c, systemsJB/T8952-2005 Metal Oxide Surge Arrester with Seamless Outer Cover for Communication System and GB311.1-1997iInsulation Coordination of High Voltage Power Transmission and Transformation Equipment.

English

English  中文简体

中文简体  русский

русский  Español

Español  عربى

عربى