The YZC New Energy Integrated Photovoltaic Prefabricated Cabin is an advanced solution designed for the centralized integration of photovoltaic systems. Pre-assembled and tested in a factory-controlled environment, the cabin offers streamlined deployment through unified transportation, lifting, and field installation.

Product Advantages

Highly Integrated System

Combines DC input, inversion, and output voltage step-up in a single compact unit.Reduces on-site construction time with factory pre-installation and testing.Supports one-step transportation, crane lifting, and connection on site, minimizing manpower and error risks.

Strong Environmental Adaptability

Designed for efficient heat dissipation through optimized ventilation.Engineered to withstand harsh conditions including sandstorms, rainfall, snow, corrosion, and sub-zero temperatures.Reliable protection ensures performance in diverse climate zones.

Stable and Reliable Performance

Compact layout with fewer failure points contributes to higher system reliability.Capable of maintaining stable operation under 20%–50% overload conditions (vegetable oil type).Long operational lifespan due to low-maintenance design.

Cost-Effective and High Return

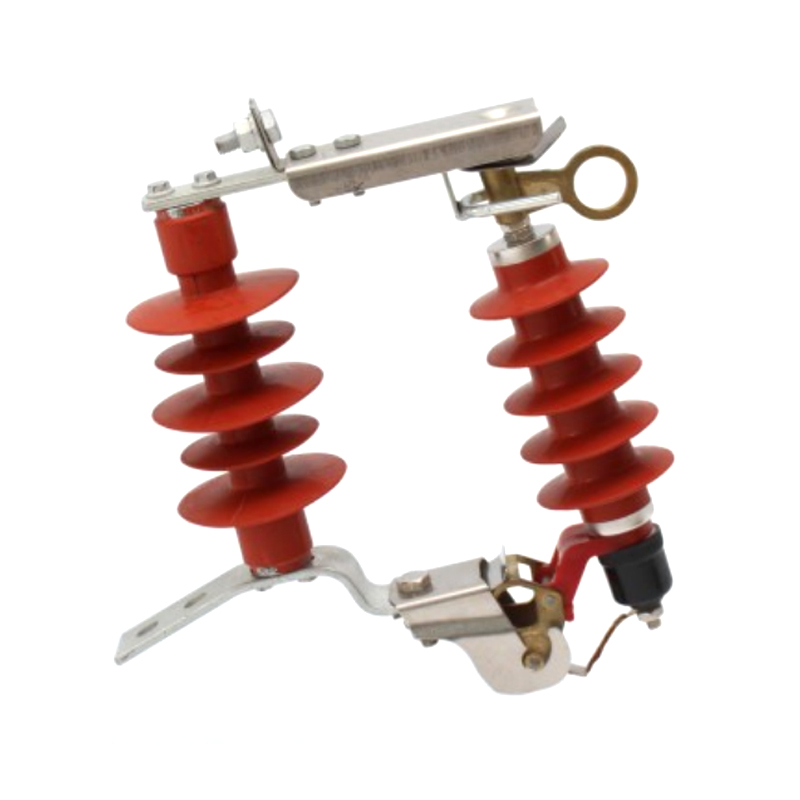

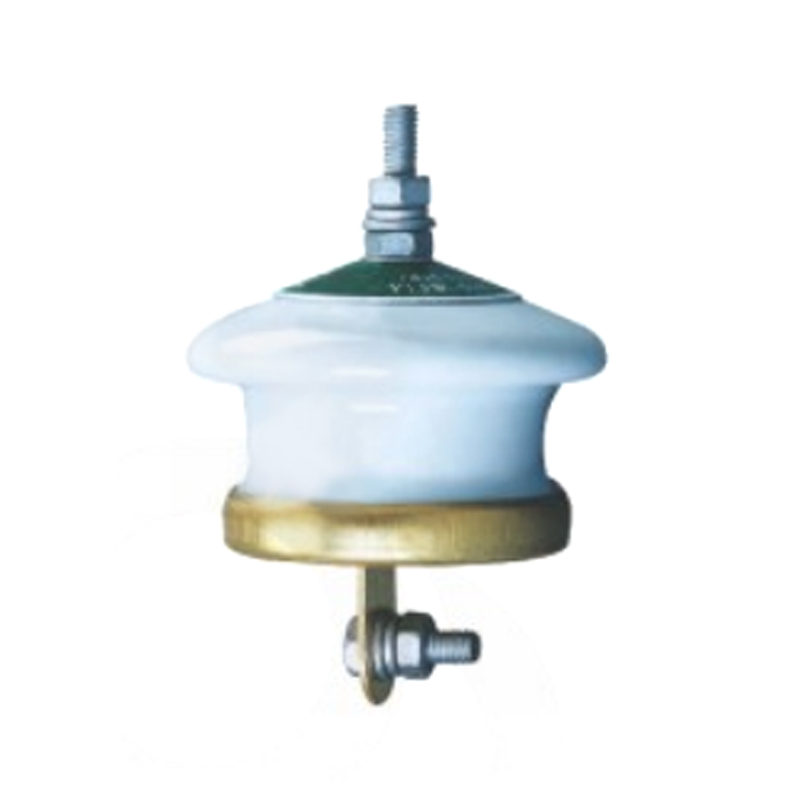

Reduces the need for extensive AC cable infrastructure.Integrates electrical protection components such as circuit breakers, lightning arrestors, power supply, and monitoring systems.Small footprint and simplified installation lower civil engineering costs and speed up project completion.

Product Features

Modular Prefabrication

Delivered as a complete module, ready for installation without disassembly.Enables quick deployment across multiple project sites with consistent quality.

Compact Structural Design

Efficient use of space allows for more flexible placement.Lightweight and crane-compatible for diverse terrains and foundations.

Comprehensive Electrical Integration

All major photovoltaic power processing components housed in a single enclosure.Supports monitoring, protection, and control systems in a centralized setup.

Safety and Protection Measures

Features internal anti-corrosion coatings, waterproof seals, and anti-dust ventilation.Built-in systems to mitigate risks from environmental or electrical hazards.

English

English  中文简体

中文简体  русский

русский  Español

Español  عربى

عربى